The idea for Corda Campus emerged in the years following the closure of the Philips manufacturing and research plant in Hasselt. Once employing thousands of workers, Philips Hasselt closed its doors in 2002 after disruptive evolution in the global electronics market. Procos Group, an Antwerp based company, specialists in space planning and facility management consulting, then put forward a masterplan to convert the site, involving both the renovation of existing Philips buildings and the construction of new offices and labs.

Reminiscent of the industrial past

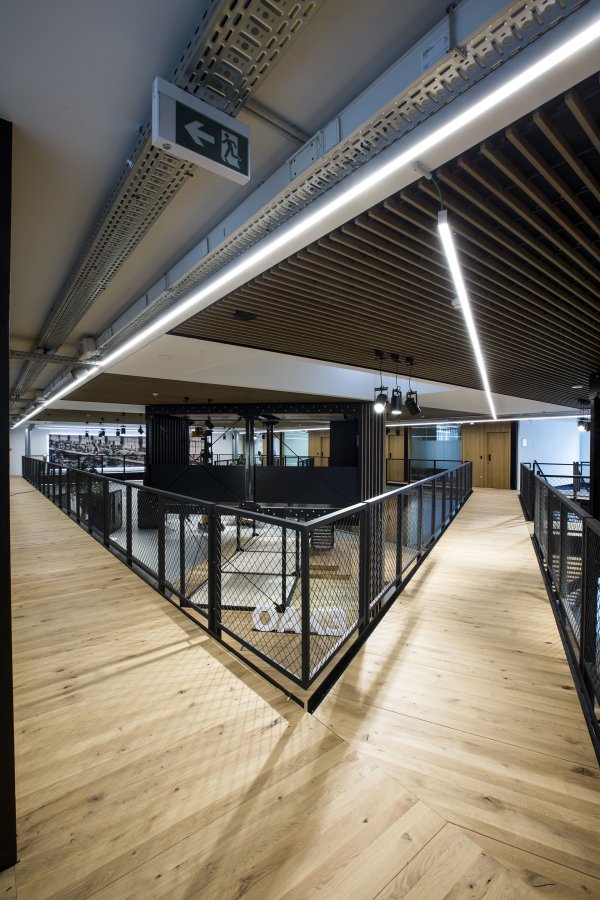

First, an eye-catching incubator building was erected, housing several technology and service start-ups. More recently, additional office and laboratory space was created by renovating and refurbishing the 3000 m² Philips production buildings. Procos Group architect Irina Vassileva elaborates on the challenges presented by the project: “We wanted to transform this old facility into an inspiring work environment where collaboration and co-creation are stimulated. Target companies would include small start-ups of a few people right up to larger companies or innovation cells with maybe sixty employees. Space organization needed to be fully optimized for both types of companies. User comfort and energy efficiency had to be top class—no compromises on that—but we also wanted the place to remain reminiscent of its industrial past. And an important practical aspect was timing: the renovation had to be completed inside six months.”